For global manufacturing leaders, workplace safety isn’t just a regulatory checkbox—it’s a fundamental social commitment and a powerful competitive advantage. Hyundai WIA, a key industrial player, embeds this belief by placing Health, Safety, and Environment (HSE) at the core of its management strategy.

Their guiding principle, “A Collaboration for a Happier Future: Safety is the First Step for a Better Future,” is supported by a robust HSE system. Applied across all domestic and international plants, this system proudly holds ISO 14001 and ISO 45001 certifications, ensuring safety is rigorously managed and constantly reinforced across the organization.

The Foundation: Governance and Data-Driven Management

A commitment to “zero-accident” starts at the top. Hyundai WIA maintains a formal, systematic Safety and Health Management System with clear accountability:

This structured approach allows for proactive risk mitigation. For example, in 2024, WIA conducted 4,560 formal risk assessments covering over 1,100 work processes, resulting in the identification and elimination of 189 high-risk cases through engineering controls.

Smart Technology: Reinforcing Safety Awareness in Real-Time

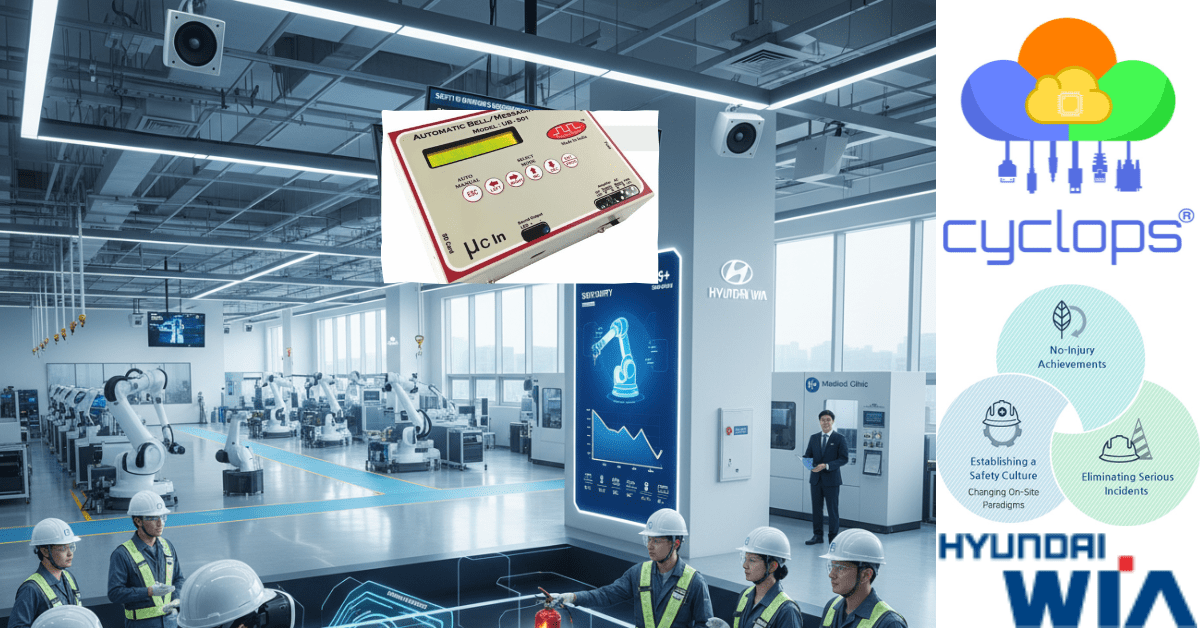

Beyond manuals and meetings, Hyundai WIA integrates advanced awareness technologies to ensure continuous vigilance on the factory floor.

A prime example is the use of automated communication systems, such as the CYCLOPS Automatic Message Announcement System. These systems act as essential real-time reminders to reinforce a culture of mindfulness:

Combining systematic management with intelligent communication enhances behavioral safety and overall workplace vigilance.

Compliance establishes the minimum; culture drives excellence. Hyundai WIA invests heavily in programs designed to internalize safe behavior.

In a truly innovative move, WIA converted a cafeteria into the S+ Safety Experience Lab at its Changwon plant. This 756 m² immersive training center is a game-changer:

2. Comprehensive Employee Health and Support

Recognizing the crucial link between health and safety, the company opened the H+ Medical Clinic on-site in 2024. Staffed by medical professionals, the clinic offers general care, occupational injury response, and specialized musculoskeletal therapy, supporting a healthier, more resilient workforce.

Extending Excellence: Collaboration Across the Supply Chain

Hyundai WIA ensures its safety standards extend beyond its own walls, actively supporting its partners and suppliers:

The Result: A Measurable Difference

This integrated, technology-backed approach has delivered clear results: by the end of 2024, Hyundai WIA had reduced its lost-time injury rates by roughly two-thirds from 2021 levels.

This reduction, affirmed by external awards and strong ESG ratings, confirms that Hyundai WIA’s commitment to a safe, healthy, and sustainable workplace is not just an aspiration—it’s an ongoing, measurable reality driven by strategic governance, culture, and innovation.

What safety innovation is making the biggest difference in your workplace?

Interested in a Demo of Advanced Workplace Safety Systems?

The innovations highlighted—from automated communication systems like CYCLOPS—are setting new industry benchmarks. If you’re ready to explore how these technologies can drive your organization toward a “zero-accident” environment, we encourage you to follow up directly with the product providers.

Call Now to inquire about product demonstrations and how these technologies can transform your safety culture!

Team

CYCLOPS SYSTEMS

Ph: +91 44 2685 2636 & 94999 22651